Or would a custom license or exception be needed for this to work and if so, would adding such exception to the GPLv3 license of the generator's source code break the compatibility with GPLv3 and/or other opensource licenses? Would it be possible to release the generator's source code (generator logic + templates) under say GPLv3 without having the generated code to be GPLv3 licensed too? The bit size is a very important consideration! Depending on your software, if the cutter is too large it will either over-cut the root and weaken the tooth, or leave a radius and not finish the involute profile or undercut.I am wondering under what license the code generated by a code generator that generates code from conditional code templates would fall under. Pro-Tip! Notes for the wood shop or anyone using an endmill to make the cut: For measuring and inspecting gears, using a Measurement Over Pins Calculator is one of the best methods to ensure your gears are perfectly in-spec. So we put the same attention to detail and mathematical skill to work for everyone.

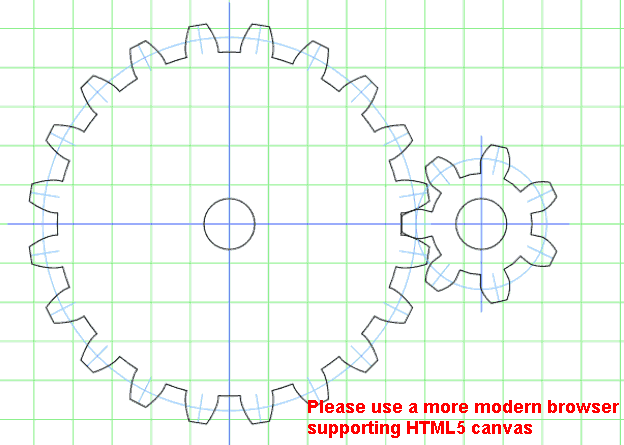

We also see low resolution involute shapes that could function better if they had the correct geometry with sufficient data points defining the involute.īeing members of the American Gear Manufacturers Association (AGMA) and having manufactured gears in most plastics and metals, the details count. This can make gears bind or function poorly. One of the more common mistakes we see in simplified gear software is the lack of undercut in small tooth count gears. Gear 1 and Gear 2 can have the same or different center hole diameters.Ĭenter Distance – This is the distance between the two shaft centers holding the gears. Another way to think about it is positive profile shift numbers will allow for more backlash between two gears en-mesh.Ĭenter Hole Diameter – Central bore hole in each gear, for standard size we’d recommend the Machinery's Handbook. A positive profile shift represents a theoretical cutter cutting deeper (leaving longer, thinner teeth), while a negative shift would cutter more shallow (leaving shorter, thicker teeth). Profile Shift – Default is 0 for most applications. To convert, use: Module = 25.4 / Diametral Pitch Module (Pitch) – this parameter sets the tooth size. The rack length defaults to the diameter of Gear 2. Gear Type – External spur gears use a positive tooth count, while internal spur gears use a negative tooth count. Tooth Count – is set with the parameter "n" for Gear 1 and Gear 2

Input the following parameters in our free gear dxf generator:.

0 kommentar(er)

0 kommentar(er)